Can Remanufacturing Build the Industrial-Sized Circular Economy?

3BL Media

DECEMBER 15, 2022

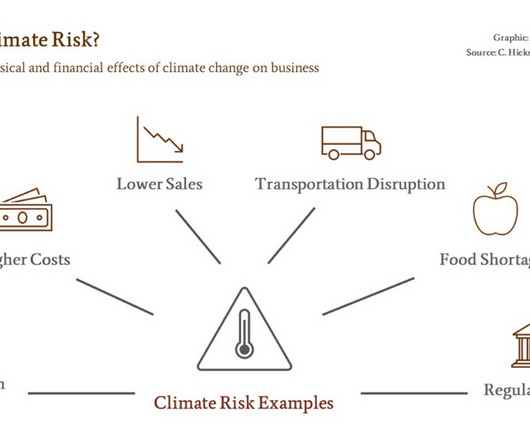

“Organizations can gain faster near-term value from bringing back existing products and reusing them for innovations that help achieve net-zero and net-neutral goals across the supply chain.”. Manufacturers are also moving factories closer to remanufacturing locations, reducing emissions from shipping and logistics.

Let's personalize your content